Printing pads

The centrepiece of pad printing

The printing pad is of central importance: not only does it give its name to the entire printing process, it also plays a key role during printing.

As an ink transfer medium, the printing pad plays a decisive role in the quality of the print. Optimum printing can only be achieved with clean, complete and distortion-free ink transfer.

Teca-Print has its own in-house pad production. Both silicone qualities and pad moulds are subject to a consistent development process.

New silicone qualities are developed in countless tests and with a great deal of practical experience.

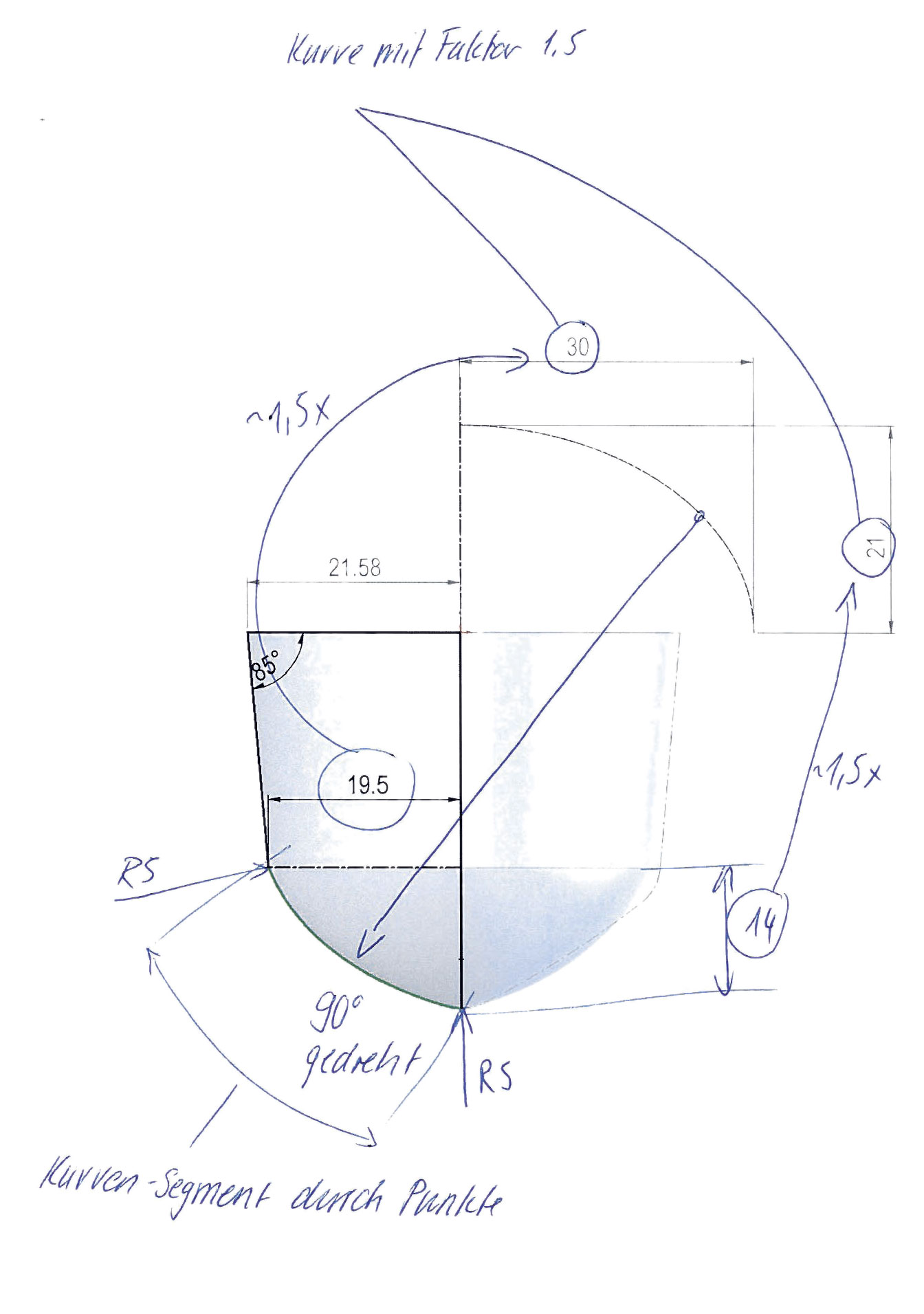

However, it is not only the properties of the silicone that influence the printing behaviour. The pad mould also determines the printing result, as it determines the rolling behaviour of the pad. Teca-Print offers you over 2,000 different pad shapes, and thanks to our consistent and customised development work, this number is constantly increasing.

Benefit from the following with our printing pads: