Teca-Print pad selector

Our pad selector allows you to choose your pad yourself.

Teca-Print Know-How:

How to find the perfect printing pad

Finding the ideal pad for many applications can be a quick process if a few basic principles are taken into account.

Simply follow our expert tips!

We have compiled the most important criteria for a successful pad selection for you. This will help you to find the ideal pad shape step by step.

Print image: design & dimension

The appearance and dimension of the print image are the first criteria to be considered when deciding on the ideal pad shape.

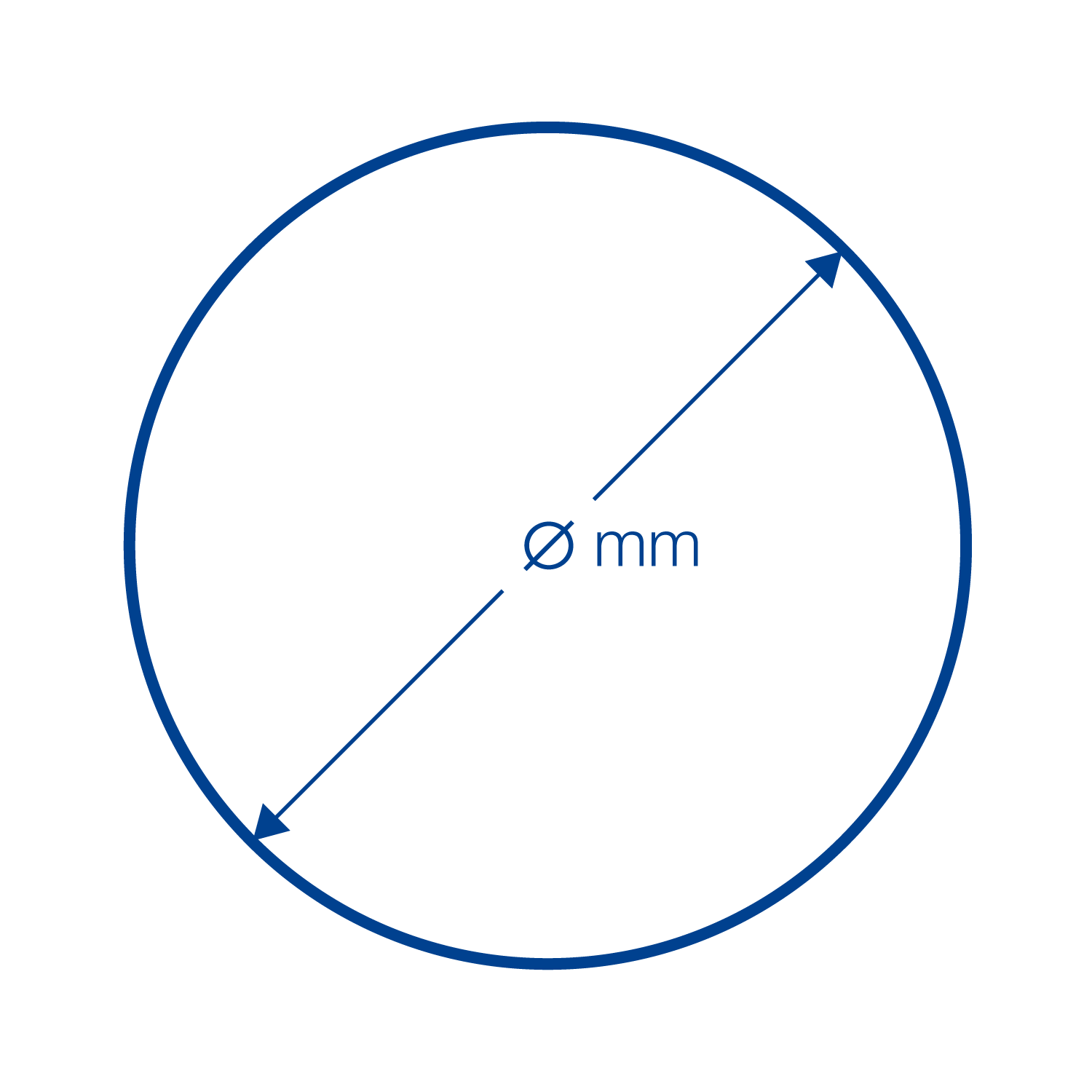

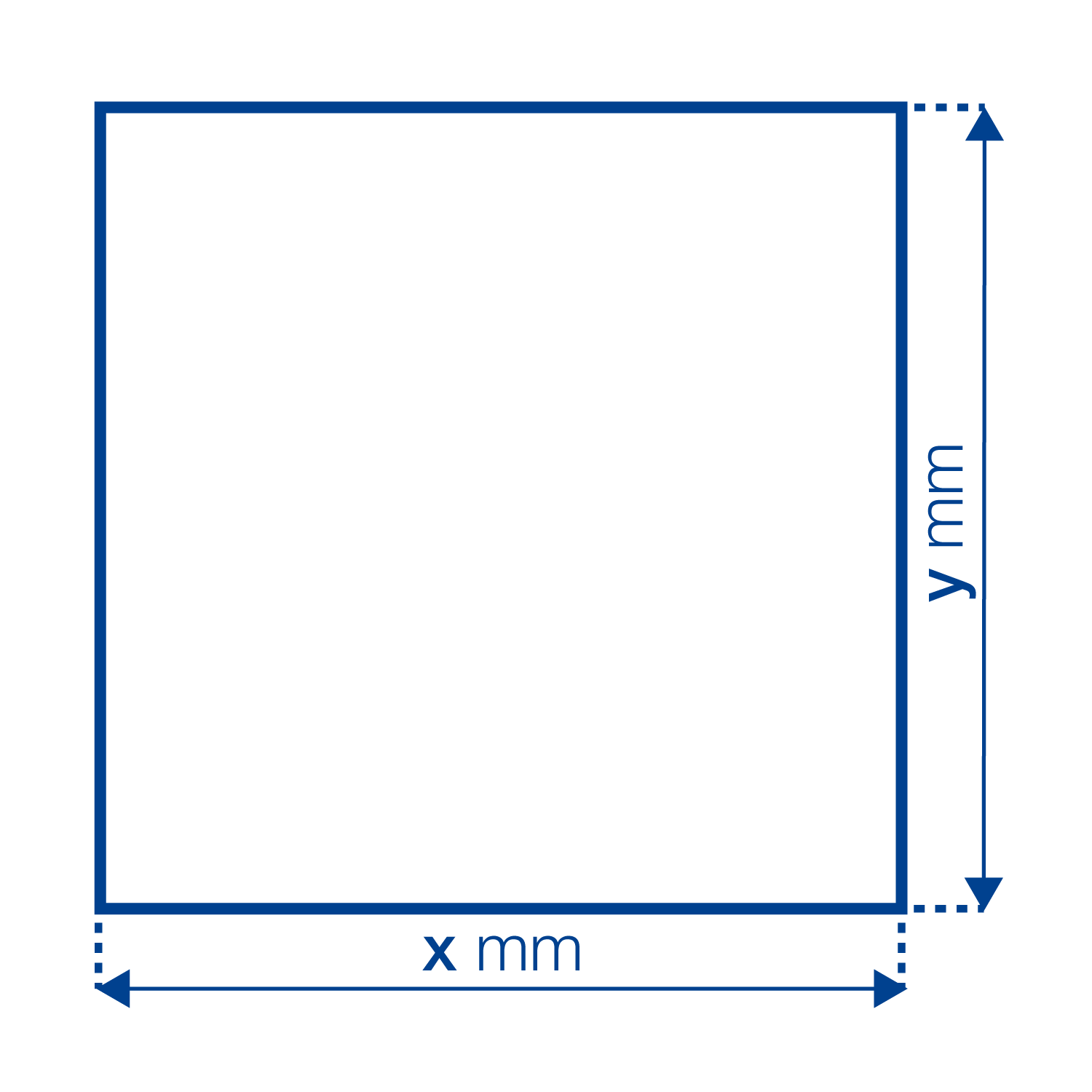

What is the size of the print image and is it round or square? There are numerous variants of both round printing pads and pads with a rectangular base.

Is the printed image full-surface or are there empty spaces?

The point or apex of a steep angled printing pad can affect the final print quality due to excessive pressure in this area. It is often possible to position a printing pad carefully to avoid picking up ink on the tip or apex and avoid this problem. But if not, then it is better to choose a printing pad with a more gentle curve and flatter surface area at the centre of the pad. If you do have clearance in the centre of the print, then you are free to choose a steep angled pad. This style of pad will deliver the highest quality prints, especially when printing from open etched cliché plates.

Print object: shape & surface

After the print image, the object to be printed determines the decision in favour of a particular pad shape.

Is the surface flat or textured?

For textured surfaces, the pad should be as sharp and hard as possible.

Is a flat object being printed or is the surface three-dimensional with raised and recessed areas? What is the position of the print image on the surface, are there raised parts or edges nearby?

The pad should not be restricted in its rolling movement by contact with elevations. The pad should be selected accordingly. For example, printing pads with fish belly shape or with an undercut are often practical for parts with elevations or edges. They often require less volume and can therefore print well closer to a raised part or edge.

Printing machine: printing pressure & available space

The selected pad printing machine also plays a role in the choice of pad.

What is the printing force of the machine? Especially with a larger print image, there must be sufficient pressure to unroll the pad evenly. Depending on the substrate, a softer hardness may be used.

The size of the pad base also plays a role, especially with multi-colour prints. The pads must be able to be placed next to each other at least within the step distance between the individual colours. This is why printing pads with a steeply tapering side are often more suitable for multi-colour prints than printing pads that have a lot of volume compared to the print area.

Overview qualities and hardnesses

Your application determines the ideal pad and silicone quality!

The printing behaviour depends on the properties of the silicone used. Teca-Print offers a versatile selection of silicone qualities to ensure the best solution for every application.

We will be happy to assist you!

The perfect shape of the printing pad has a decisive influence on the quality of the printed image. Depending on the print image, pad printing machine and ink used, it is important to find the optimum pad shape.

We at Teca-Print will be happy to advise you in detail and help you to find the perfect shape. Our printing pads and moulds are developed and manufactured in our in-house laboratory.

Write to us or give us a call, we would be pleased to give you personalised assistance!